Solutions for Production Logistics

We tailor in-depth customized services for the production lines of customers, providing different solutions to the specific characteristics of different workshops in automobile production, which include site planning, equipment application, personnel management, etc. By integrating AGV, electronic Kanban, pick-to-light equipment, unmanned forklifts, and other equipment to ensure smooth and efficient line feeding

Professional On-site Logistics for Automobile Parts Factories

● In-plant operation services, such as goods receiving, repacking, storage, picking, line feeding, and internal material transfer

● On-site value-added services, such as site management, fixing tools management, secondary assembly, completely knock down/semi-knocked down, waste recycling and management, AGV automated navigation and storage systems, pick-to-light, electronic pull production systems, and more

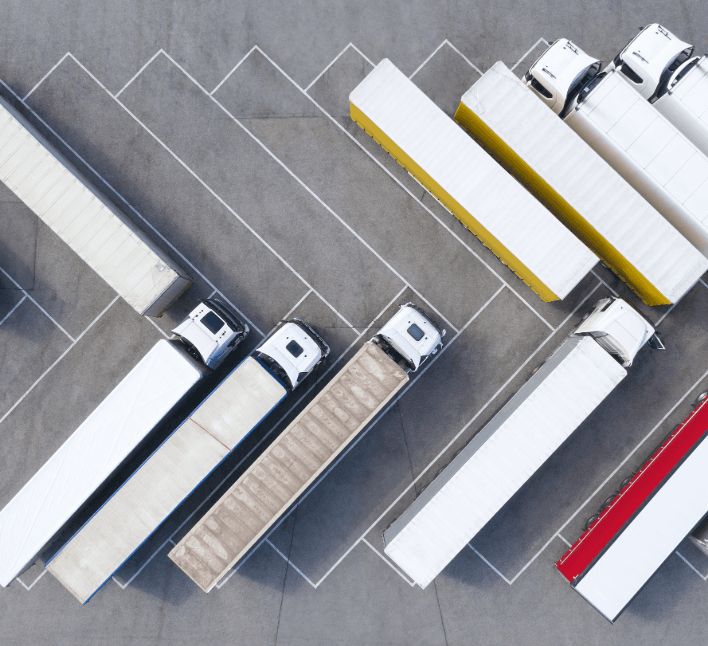

Professional On-site Transportation for Automobile Parts Factories

● On-site shuttle buses

● Unloading and transportation in container yards, including waste and heavy metal transportation

This solution is suitable for OEMs in the following fields:

On-site Logistics: Assembly Line Operations

On-site Transportation

Completely Knock Down/Semi-knocked Down